POWER ELECTRONICS

Power Electronics

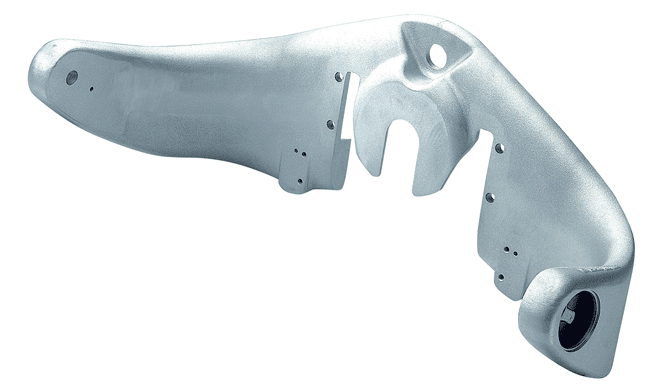

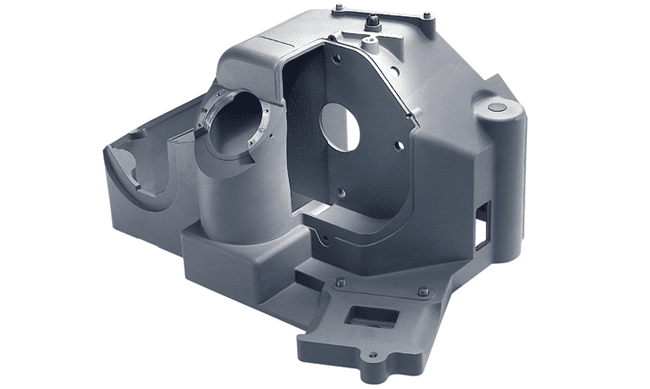

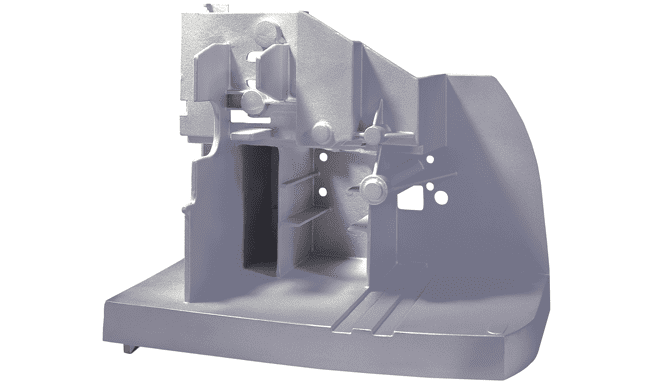

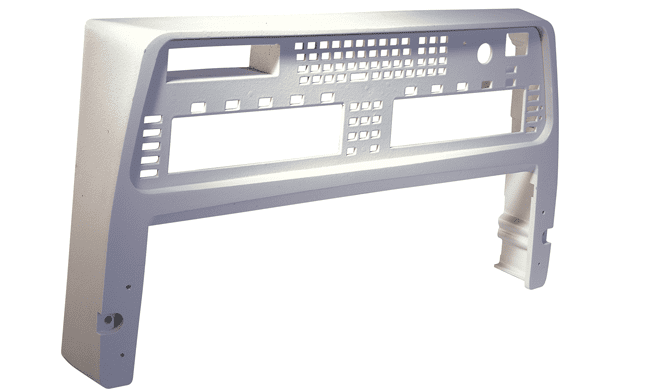

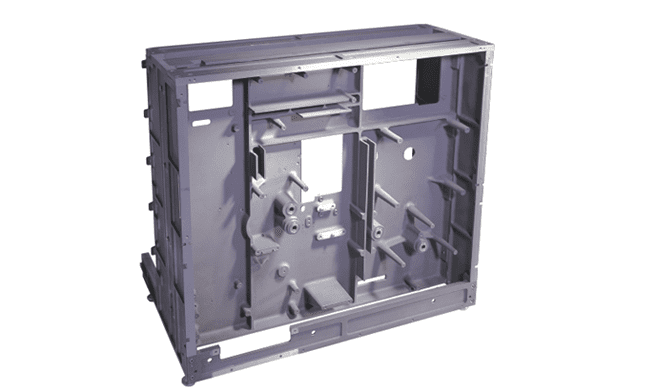

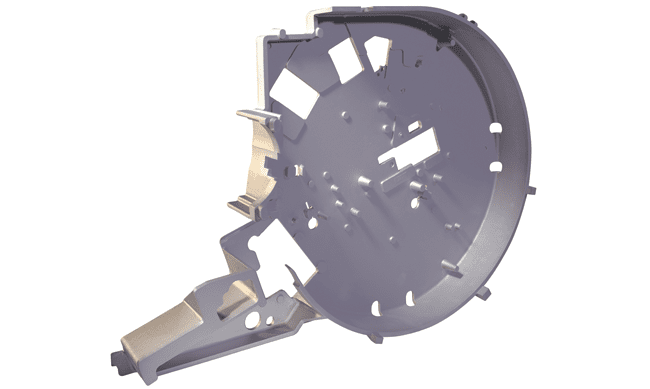

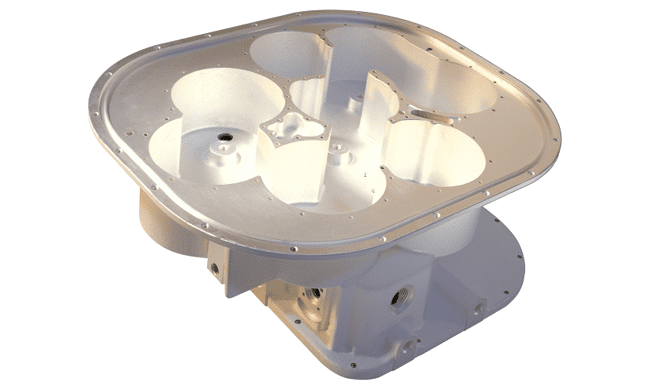

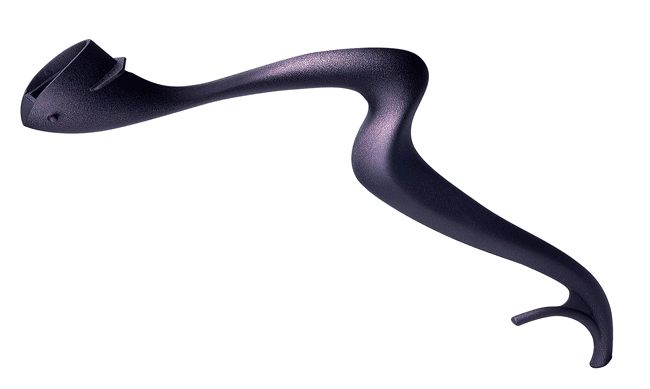

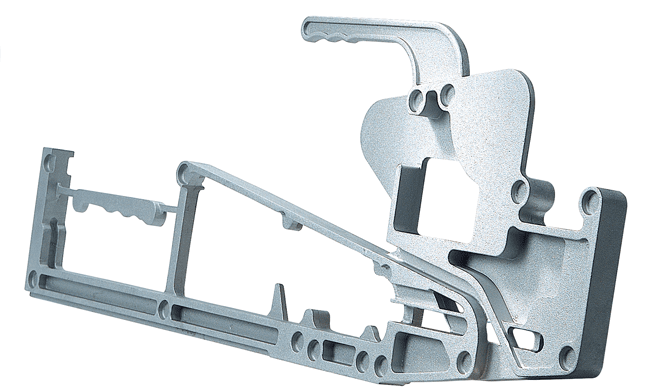

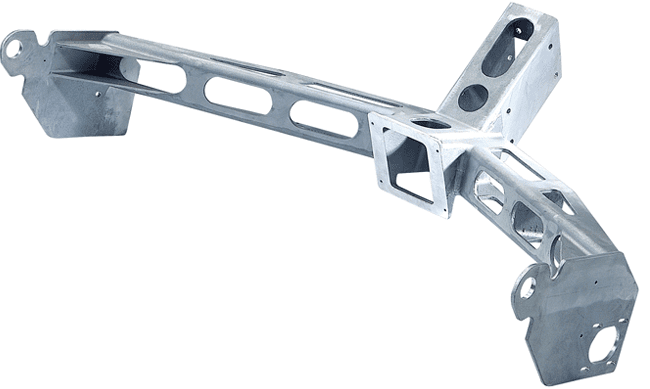

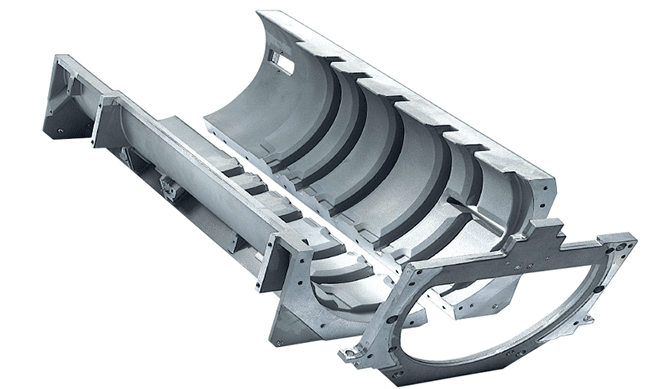

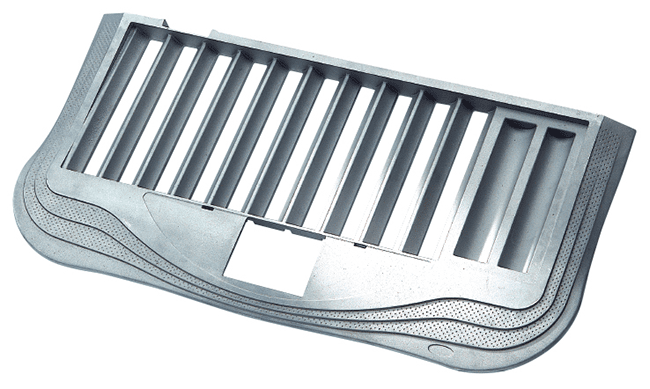

With the ability to produce castings with zero draft, thin walls, and excellent surface finishes, Harmony is a key supplier to the electric and hybrid vehicle markets, as well as the battery industry. These capabilities enable engineers to design lighter, more compact enclosures and housings. With patterns built in just two weeks, first articles can be delivered within 3-4 weeks, allowing customers to rapidly enter the market. Our patterns are not only quick and cost-effective to revise, but also highly durable, ensuring consistent tolerances and repeatability throughout production.

Typical Applications

- Motor Controller Enclosures

- Battery Disconnect Units

- Inverter Housings

- Battery Enclosures

- PCB Housings

- DC-DC Converter

Key Features and Benefits

- 150 RMS Finish

- Quick Pattern Revisions

- Speed to Market

- Excellent Casting Integrity

- Zero Degree Draft

- Tight Tolerances

- Thin Walls